Offshore Generator Sets:

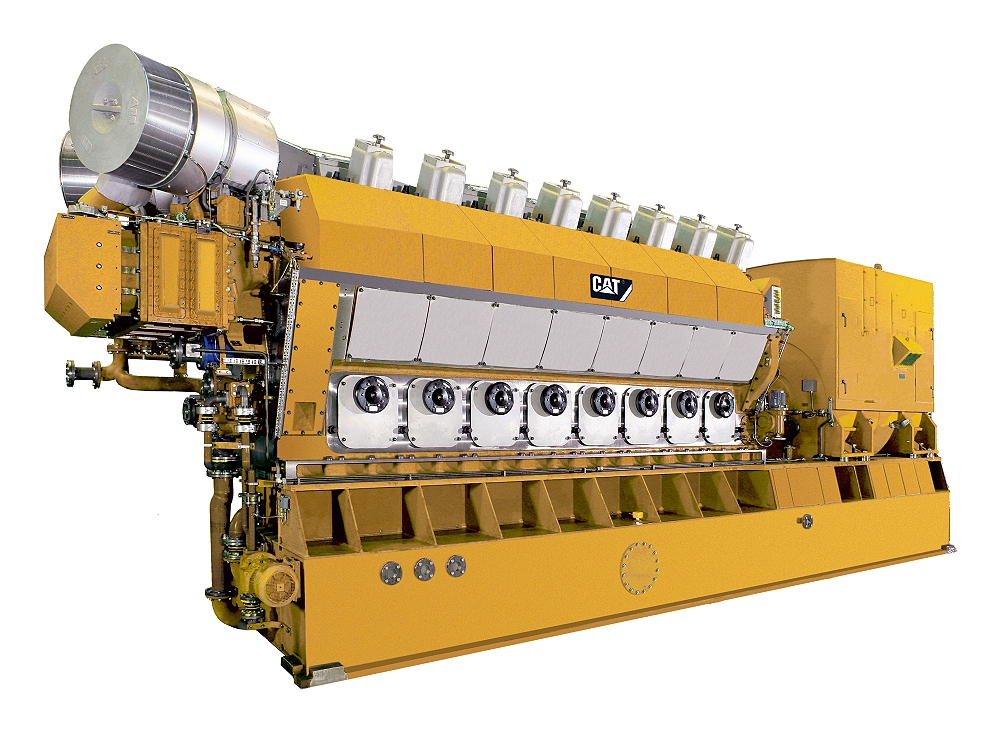

16CM32C Offshore Generator Set

Click a link to download the document:

- Aspiration

- Turbocharged-Aftercooled

- Stroke

- 18.1 in

- Bore

- 12.6 in

- Displacement

- 36126.0 in3

The 16CM32C generator set brings to the offshore oil and gas industry a legacy of proven reliability and durability. CM offshore generator sets feature standard modular designs, engine-mounted pumps and filters, and a full range of factory attachments that make their installation simple and efficient.Ideal applications for the 16CM32C offshore generator sets are main power on-board drilling and production vessels and platforms.Complete package offerings are MCS type-approved and compliant with IMO Tier II emissions standards, making their integration into vessels and platforms a simplified operation.Cat generator sets are backed by the worldwide network of Cat dealers ready to support your operation with technical support, service, parts, and warranty.Cat 16CM32C offshore generator set. Ratings: 7760 – 8690 ekW (9700 – 10860 kVA) @ 50/60 Hz (750/720 rpm). IMO Tier II emissions compliant.

Product Specs

-

Engine Specifications

- Aspiration

- Turbocharged-Aftercooled

- Stroke

- 18.1in

- Bore

- 12.6in

- Displacement

- 36126.0in3

- Minimum Rating

- 5460kV·A

- Maximum Rating

- 5460kV·A

- Emissions

- IMO Tier II

- Engine Control

- Electronic

- Generator Set Control

- Electronic

- Weight

- 330000lb

- Aspiration

- Turbocharged-Aftercooled

- Bore

- 12.6in

- Displacement

- 36126in³

- Stroke

- 18.1in

-

Dimensions

- Length

- 474.8in

- Height

- 222.9in

- Width

- 118.1in

- Height

- 222.9in

- Length

- 474.8in

- Width

- 118.1in

-

Capacity for Liquids

- Cooling System (Engine)

- 502.0gal

- Lube Oil System (Refill)

- 2853.0gal

- Cooling System - Engine

- 502gal (US)

- Lube Oil System - Refill

- 2853gal (US)

Equipment

-

- Engine

-

- Motor-driven barring gear, fitted on engine

- Reversing contractor and push button switch with cable

- Electronic speed setting equipment with actuator and speed pick-up

- Emergency shutdown equipment with pushbutton, separate, formanual emergency stop

-

- Engine Indicators

-

- Gauge board with set liquid damped pressure gauges for:fuel, lubricating oil, fresh water, starting air, and charge air.

- On-engine thermometers for fuel, lubricating oil, fresh water,and charge air

- Electric remote speed indicator

- Turbocharger and remote speed indicator

- Exhaust gas temperature indicator

-

- Control

-

- Manual control on engine, including: control panel with start /stop key, speed setting device, mechanical shutdown device, change over of control functions from engine to remote control

- Starting solenoid valve on engine, 24 V DC

- Separate electronic speed governor

-

- Monitoring For Unattended Operation

-

- Pressure switches, mounted on engine, for:

- Switches for:

- Control Cabinet with housings for wall mounting, including:

-

- Starting Air System

-

- Separate non-return valve for the starting air pipe to the engine

-

- Air Intake System

-

- Air intake filter, fitted on the turbocharger

- – Air bottles, separate

-

- Fuel System

-

- Separate circulating pump driven by electric motor, horizontalor vertical

- Duplex filter with differential pressure indication

-

- Exhaust System

-

- Turbocharger at free end with transition nozzle (0 degrees from the vertical and away from engine), with compressor cleaning device

- Expansion joint separate

- Separate silencer and spark arrester, unlagged 35 dB(A)

-

- Fresh Cooling Water System

-

- HT pump, fitted on engine

- LT pump, separate, vertical design, electric motor driven

- HT thermostat, not powered and separate

- Engine preheating equipment, fitted on base frame

-

- Lubricating Oil System

-

- Plate cooler, fitted on engine

- Force pump, fitted on engine

- Prelubrication pump, fitted on base frame, electric motor driven

- Boll and Kirch automatic backflushing filter, separate

- Duplex filter with differential pressure indication, separate

- Pressure control valve, separate

- Thermostat, not powered, separate

-

- Connecting Parts – Engine

-

- Set of connecting parts between flange coupling and flywheel

- Flexible flange coupling between engine and generator

- Base frame with flywheel guard and incorporating lube oil sump tank,for engine and generator

- Mounting of engine and generator on the base frame

- Set of bonded rubber rails for resilient mounting of the base frame

- Set of flexible pipe connections

-

- Tools

-

- Set of tools for the engine including hydraulic tightening tools and nozzle tester

- Set of tools for turbocharger

- Inside micrometer for cylinder liners

- Ruler for cylinder liner

-

- Spare Parts

-

- Set of engine spare parts for unrestricted operation

- Set of spare flexible pipe connections